This exciting technology is exploding with new developments that make automation and electronic systems even more efficient, productive, and safe. Many of them can be applied to numerous manufacturing and processing industries in the U.S. and worldwide.

3D printing for manufacturing and 24-hour manufacturing and processing are two of them. Two others include storing wireless data on the cloud and creating invisible seams with diode lasers. A major player in this technology is robotic sensing, measuring, and process control. This discussion delves into how they are improving automation and electronic systems technology.

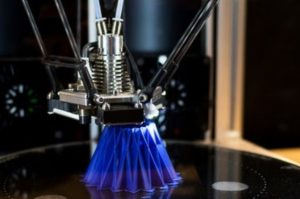

3D Printing for Manufacturing

Three-dimensional (3D) printing is one of the greatest advances in manufacturing automation. The latest machines are small enough to be more convenient and faster for greater production for almost any business. They produce finished parts and are capable of improving accuracy on larger projects. Its use is becoming widespread in both private enterprises and the military.

Automated 3D printing has some significant advantages over traditional manufacturing:

- Manufacturing is more affordable for some products

- Complex and customized designs can be made with less human error

- Some 3D products are stronger and lighter

- Some products need less human effort for assembly

- Machines can be designed to produce multiple product lines

They are the rage for opening up new supply chains and retail opportunities.

24-Hour Manufacturing and Processing

A dream-come-true for many manufacturers is continuous, 24-hour manufacturing conducted by robotic operations. It’s now upon us and the seven days a week, 365 days a year production is a reality for many companies. Repeatable processes can be accomplished with amazing precision and accuracy.

A dream-come-true for many manufacturers is continuous, 24-hour manufacturing conducted by robotic operations. It’s now upon us and the seven days a week, 365 days a year production is a reality for many companies. Repeatable processes can be accomplished with amazing precision and accuracy.

A decade ago the initial expense of using robotics was out of reach for many companies. More companies can afford this technology with today’s lower prices as low as 50% compared to three decades ago. Manufacturers and processors produce greater productivity and efficiency at more competitive prices.

Storing Wireless Data in the Cloud

Cloud storage of information benefits virtually every industry around the world by:

- Storing most or all of a company’s data wirelessly

- Data from machines can be automatically uploaded to the cloud

- Information is backed up over this wireless network

- Once data is uploaded, it is safe from computer malfunctions

- Data is accessible from any computer on or off the company site

The cloud also allows employees and managers to access information when traveling, at a customer’s business, or from home.

| “This exciting technology is exploding with new developments that make automation and electronic systems even more efficient, productive, and safe. Many of them can be applied to numerous manufacturing and processing industries in the U.S. and worldwide.” |

Creating Invisible Seams with Diode Lasers

One of the eyesores we have all had to live with on many products is the visible welding seams on joined materials. Diode lasers are used to create smaller, and in many cases, almost invisible welding seams. These welds can also provide additional structural integrity in products of many types and metals.

One of the eyesores we have all had to live with on many products is the visible welding seams on joined materials. Diode lasers are used to create smaller, and in many cases, almost invisible welding seams. These welds can also provide additional structural integrity in products of many types and metals.

Welding, bonding, and soldering metal joints are processes used by thousands of companies. Diode lasers can be programmed to do this work more effectively and efficiently to reduce production time and costs. Its use in automation and electronic systems technology will continue to grow by leaps and bounds.

Robotic Sensing, Measuring, and Process Control

You can’t say automation and electronics in manufacturing without robotics. These machines are more sophisticated and are taking on more human-like abilities. Process control devices guide these marvels with the information needed to operate effectively and accurately.

You can’t say automation and electronics in manufacturing without robotics. These machines are more sophisticated and are taking on more human-like abilities. Process control devices guide these marvels with the information needed to operate effectively and accurately.

Advanced electronic technology allows robots to sense and measure activities that allow more precise work with fewer employees. Sensing components are measuring devices in the feedback loop that monitor the values of output variables.

Sensors can detect slight negative changes in operations and alert the system, operator, or plant manager to make corrections. The alerts can go to cell phones or computers for faster reaction times. The process control devices compare the measured output value with the standard value and reduce the differences.

Where You Can Learn How to Work in This Technology

Learn what it takes to earn an entry-level job in Automation and Electronic Systems Technology at ITI Technical College in Baton Rouge. Our Associate of Occupational Studies (AOS) Degree in this program teaches the knowledge and skills to excel in this career. Since 1973 we have graduated thousands of students in technical programs who have found solid employment.

For more information about graduation rates, the median debt of students who completed the program, and other important information, please visit our website at: https://iticollege.edu/disclosures/