The role of automation and electronic systems in modern manufacturing is growing every day. Robotics and programmable logic controllers (PLCs) are continuing to revolutionize industrial processing worldwide. Their impact on productivity and efficiency is enormous as structured advances are made.

Although some products are still made manually by master craftsmen, they are in the minority. The worldwide demand combined with fewer people who want to work in manufacturing has fueled automation. Global competition and controlling consumer prices demand that making quality products faster and more efficient is imperative.

Today’s manufacturing and processing workforce requires advanced training and education to keep their companies profitable. The best employees hold college degrees in automation and electronic systems technology.

The Future of Manufacturing Automation

We use products in our personal and professional lives every day that are created by automation in factories and processing plants. Examples include phones, automobiles, bread, and furniture. Since most of us do not work behind the scenes in factories, we do not understand the extent of production automation and electronics systems.

The future of manufacturing automation builds on today’s production and processing lines. A 2023 study conducted by Kissflow reveals these positive statistics:

- 67% of companies currently use business process automation to streamline and automate their daily repeatable tasks.

- 31% of companies have fully automated at least one of their major functions.

- 83% of IT leaders believe that workflow automation is crucial.

- 68% of employees have too much work to handle daily and need help.

The percentage of almost all companies using automation to some extent will grow dramatically in the future. This is especially true of manufacturing and processing plants.

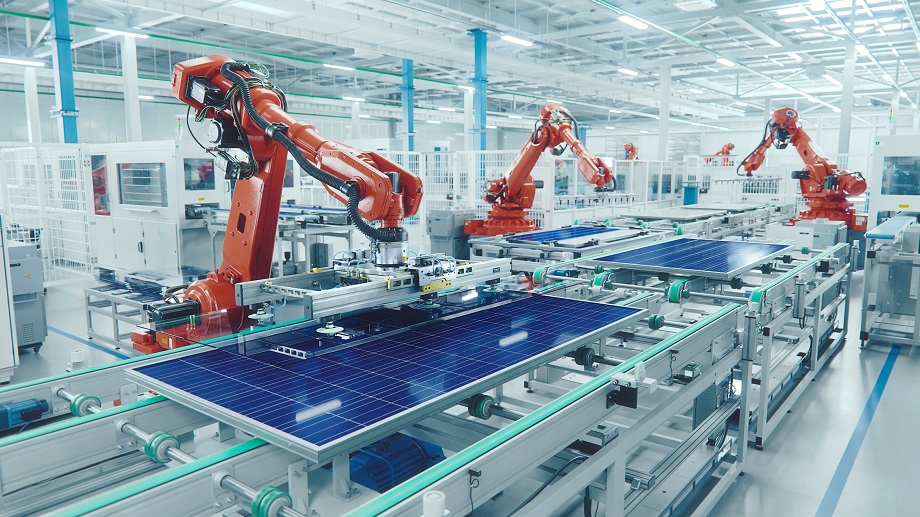

Robotics In The Future Of Manufacturing Automation

If you took a tour of a manufacturing facility that is highly automated, you would be amazed!

Robots are programmed to perform effectively and provide numerous benefits, such as:

- Improved efficiency

- Higher precision

- Better quality

- Perform welding and cutting operations

- Do machining and molding

Robots perform these functions with a high degree of accuracy and repeatability. This reduces errors and reworking parts and ensures consistent production of high-quality parts. The future of robotics will be more sophisticated to include advanced decision-making, reporting, more specialized work, easier integration with other systems, increased capabilities, and performing more complex tasks.

| “The role of automation and electronic systems in modern manufacturing is growing every day. Their impact on productivity and efficiency is enormous as structured advances are made.” |

Programmable Logic Controllers (PLCs)

The role of programmable logic controllers (PLCs) is to automate and monitor manufacturing processes by sending programmed control functions. The functions are sent to output devices based on signals received from input devices. The input devices measure and transmit data from sources, such as computer software, switches, relays, sensors, or thermometers.

Machine learning algorithms and IIoT applications along with evolving technologies are increasingly introduced into manufacturing and processing facilities worldwide. PLCs will play more important roles as processors of real-time manufacturing data. Manufacturers will adapt to the changes in electronic and automated operations to stay on top of their games.

Impact On Productivity And Efficiency

Today’s business owners must know their needs in-depth and obtain the right software to get the most out of workflow automation. We have already mentioned some benefits of robotics and automation, and here are some more:

|

|

|

|

|

|

|

|

|

Digitization and automation when combined create new technical opportunities for organizations. They also produce better management of work tasks and employees and streamline many manufacturing and processing operations from start to finish.

Digitization and automation when combined create new technical opportunities for organizations. They also produce better management of work tasks and employees and streamline many manufacturing and processing operations from start to finish.

Automation and robotics operated by advanced electronic systems produce more products in less time, at higher quality, and at lower costs than old-style systems. It is safe to say their impact on productivity and efficiency can only go one way and that is up.

Your Best Opportunity Is Earning A College Degree

You may be wondering how automation, robotics, and electronic systems relate to a college degree. Enroll in the Automation and Electronic Systems Technology Program at ITI Technical College and you will find out. Our Associate of Occupational Studies (AOS) Degree teaches:

- Real-world skills in analog and digital electronics including microprocessor control

- Training on the use of equipment used in troubleshooting electronic control systems

- The use of digital multimeters, oscilloscopes, function generators, and logic probes

- Skills in programmable logic controllers and a networking course

- The application of low voltage and fiber terminations related to automation

- Learn to work with I/O systems and the Arduino platform

- Essentials in basic computer applications and technical writing

Learn more about this exciting and rewarding program and prepare yourself for an entry-level position in automation and electronic systems technology. Call us today at (877) 591-1070 for more information about all our programs!

For more information about graduation rates, the median debt of students who completed the program, and other important information, please visit our website: https://www.iticollege.edu/disclosures