Manufacturers are constantly on the search for more efficient and productive ways to make products while maintaining quality and reducing costs. Other significant goals include reducing waste and creating more worker safety. One of the best ways to achieve these objectives is by using 3D printing for design, drafting, and manufacturing. Contact ITI Technical College today for more information.

3D technology is not limited to designing, drawing, and making small objects. It is expanding rapidly to include making larger objects and products, such as statues, boats, rockets, life-size dinosaurs, and houses. This method is an ingenious way to stay up with or surpass domestic and global competition.

What Is 3D Printing Technology?

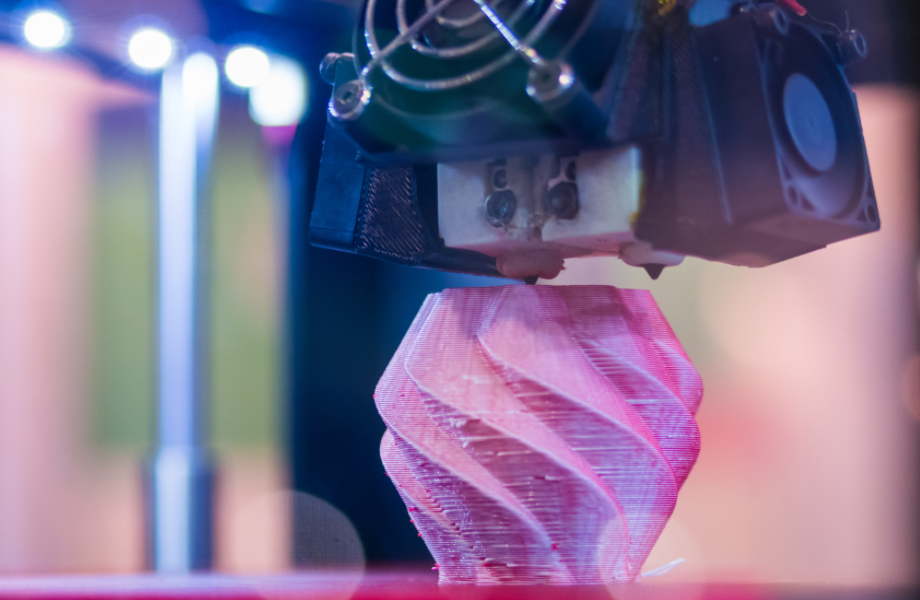

3D printing is an additive manufacturing technology that creates three-dimensional objects by adding layers of material on top of each other. A computer forms objects with digital files from liquids, metals, powders, plastics, and other materials. The process uses a combination of software, materials, and precision tools to create three-dimensional objects from scratch.

3D printing is an additive manufacturing technology that creates three-dimensional objects by adding layers of material on top of each other. A computer forms objects with digital files from liquids, metals, powders, plastics, and other materials. The process uses a combination of software, materials, and precision tools to create three-dimensional objects from scratch.

Many different software tools are available, and many beginners start with Tinkercad. It is free software that works in your browser and does not need to be installed on your computer. It has a built-in feature to export your model as a printable file. Once you have a printable file, you prepare it for your 3D printer which is called slicing.

Slicing means dividing up or slicing a 3D model into hundreds or thousands of layers with slicing software. Once the file is sliced, it is ready for your 3D printer where you feed the file with USB, SD, or Wi-Fi. The file is now ready to be 3D printed layer by layer to create an object.

A variation called volumetric 3D printing technology is primarily in the research phase. It is based on printing entire structures at once without the need for layer-by-layer fabrication.

Using 3D Technology

3D printing enables designers, drafters, and engineers to bring their ideas to life in ways that were unimaginable a few decades ago. This technology allows technicians and engineers to produce intricate designs with greater accuracy and precision. The results are improved product quality, functionality, less cost, and waste. There are other advantages and features:

- Ability to rapidly iterate designs and create prototypes

- Significantly reduce time in manufacturing

- It is a powerful tool for innovation in design and drafting

- Easily modify designs for customers’ customized products

- Create efficient prototype designs

- Create unique designs with complex geometries

- Design optimization for purpose-driven solutions

This technology offers unrestricted design possibilities and eliminates many constraints imposed by traditional manufacturing and construction. It allows designers and drafters to explore different forms, shapes, and structures that expand the boundaries of design and innovation. 3D printing is revolutionizing the way we think about and approach design and drafting. It allows the creation of unique and personalized products to meet individual ideas, needs, and preferences.

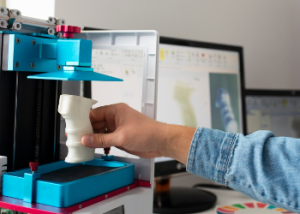

3D printing can produce complex drawings and geometries that have been difficult or impossible to manufacture. It can accelerate the product development process and open innovation across various industries. Designers can create functional prototypes directly from the CAD models faster than before. This allows for rapid testing and refinement of designs before committing to product production. Designers can easily test and refine designs through multiple iterations that lead to better product outcomes.

|

“One of the best ways to achieve these objectives is by using 3D printing for design, drafting, and manufacturing.” |

The Advantages Of 3D Printing

3D printing processes greatly reduce material waste by only using what is necessary for the print (product or object) and its support structures. Compared to other manufacturing methods like injection molding or CNC machining, the material is not removed from a block of material which results in a lot of waste. Other advantages of this design, drafting, and manufacturing method:

3D printing processes greatly reduce material waste by only using what is necessary for the print (product or object) and its support structures. Compared to other manufacturing methods like injection molding or CNC machining, the material is not removed from a block of material which results in a lot of waste. Other advantages of this design, drafting, and manufacturing method:

- Accessibility

- Cost-Efficiency

- Design Flexibility

- Healthcare Applications

- On-Demand Production

- Quality Assurance

- Rapid Prototyping

- Supply Chain Enhancement

- Sustainability

Individuals and small businesses have more opportunities to level the playing field with larger manufacturers. They can design, draw, and make products with innovation, speed, and accuracy like never before. They no longer need expensive equipment and machinery or specialized knowledge and skills to make some products.

3D printing is shaping the future of drafting and design in multiple ways. It is carving out a manufacturing technique that is revolutionizing product design and development. Let the future of 3D printing design and drafting technology be part of your career by enrolling in our Drafting & Design Technology (AOS) Associate In Occupational Studies Degree Program.

For more information about graduation rates, the median debt of students who completed the program, and other important information, please visit our website: https://iticollege.edu/disclosures/