Mechanical drafting and design professionals are also known as CAD and CADD operators and AutoCAD designers. They use computer-aided design (CAD) software to create plans and drawings with technical details. Users find this software easy to manipulate such as modifying plans as they design or after the drawings are finished.

Computer software products allow drafting and design employees to print their work for current use and save their plans for future projects. Users can interface technical drawings with a manufacturing system to produce parts, devices, or machinery. Graduating from a technical college with an associate degree in drafting and design technology is the best way to enter a career. The following information will help you understand what you need to know about mechanical drafting and design.

What Mechanical Drafting and Design Pros Do

Mechanical drafting and design pros convert sketches, designs, and notes from mechanical engineers and factory operators into technical drawings. These drawings serve as detailed working diagrams that form the basis for manufacturing components, devices, tools, and machinery. Drafters and designers work in many different industries and their services are indispensable in production work.

Mechanical drafting and design pros convert sketches, designs, and notes from mechanical engineers and factory operators into technical drawings. These drawings serve as detailed working diagrams that form the basis for manufacturing components, devices, tools, and machinery. Drafters and designers work in many different industries and their services are indispensable in production work.

The layouts and drawings indicate requirements for the production and/or assembly of parts and completed products. Drafters spend most of their time drawing and designing on computers and on paper but sometimes visit job sites for clarifications of plans. They use their knowledge of and skills in:

- Design and Drafting techniques

- Engineering Technology applications

- Mechanical Devices and their uses

- Mathematics including algebra, geometry, and calculus

The specific responsibilities of mechanical drafting and design employees depend on the industry and the company where they work.

Mechanical Drafting and Design Standards Are Important

Mechanical Drafting and Design pros use industry standards to create world-class work. One of the standards is using a conventional drafting language because it is so useful for:

- All professionals’ understanding of drawings

- Other people duplicate technical drawings

- Communicating strict specifications and details

- Anyone who acquires parts or equipment needed for projects

- Engineers who are involved in generating the products

Upholding these standards improves the quality of components, tools, and machinery so companies can stay competitive.

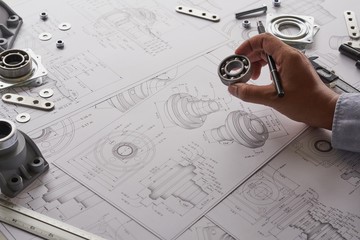

Drawing details communicate lists of materials needed, dimensions to follow, shapes, and how components fit together. Tolerances for parts are included in some drawings and plans. Some companies also have their own set of standards to unify certain technical drawings.

Types of Technical Drawings

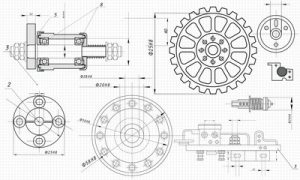

There is no one type of technical drawing for those who work in mechanical drafting and design. They may find it necessary to have a set of drawings or plans for some types of projects such as those with complicated parts or large sizes. When this is the case, each drawing will show a different set of details or different perspectives. Basic types of drawings include:

There is no one type of technical drawing for those who work in mechanical drafting and design. They may find it necessary to have a set of drawings or plans for some types of projects such as those with complicated parts or large sizes. When this is the case, each drawing will show a different set of details or different perspectives. Basic types of drawings include:

- Assembly drawings show how components or parts fit together to create products.

- Detail drawings exhibit dimensions, specifications, field notes, or material lists.

- Elevation front-view drawings show how objects look from the front.

- Top-view drawings show how objects appear from the top.

- Side-view drawings show how objects look from the side.

| “Mechanical drafting and design professionals are also known as CAD and CADD operators and AutoCAD designers. They use computer-aided design (CAD) software to create plans and drawings with technical details.” |

Tools and Equipment

Mechanical drafting and design workers use traditional tools and equipment as well as industry software packages. CAD software is easier to understand when students and employees have learned the principles and techniques of freehand drafting. Drawing on paper allows people to use more creativity and originality in their work. Here are some conventional tools in use:

Mechanical drafting and design workers use traditional tools and equipment as well as industry software packages. CAD software is easier to understand when students and employees have learned the principles and techniques of freehand drafting. Drawing on paper allows people to use more creativity and originality in their work. Here are some conventional tools in use:

- Blueprint measuring tools, compasses, and irregular curves

- Drafting dividers, drafting paper, drawing boards

- Protractors, reference and Light tables, and scales

- Stencils, stools, tape, triangles

- T-squares, and drawing tubes

All these tools, equipment, and software packages are part of an associate degree in drafting and design technology.

Where to Find Mechanical Drafting and Design Education

A great place to earn your credentials is ITI Technical College. Our Associate of Occupational Studies (AOS) Degree in Drafting and Design Technology provides the training you need for an entry-level job in your career. Request more information today!

For more information about graduation rates, the median debt of students who completed the program, and other important information, please visit our website: https://www.iticollege.edu/disclosures