Process design and process technology are parts of a specialized branch of process engineering where technicians work under the direction of engineers. They form a team to work with robotics, electrical systems, mechanical systems, and control systems. The team also conducts safety training related to processing systems.

Commercial and industrial operations management includes designing equipment and the technologies that cover these processing and manufacturing concepts:

- Chemical processes

- Physical processes

- Mechanical processes

- Biological processes

Operations and processing management also cover production scheduling and planning project budgets. To better understand process design, you need to explore process technology, its functions, the skills and knowledge needed for the job, and the types of available jobs.

Process Design Is Part of the Process Technology

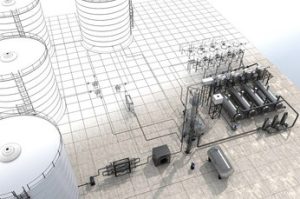

Process technology forms the basis for creating products for commercial, industrial, and personal use worldwide. Processing equipment and lines of flow must be designed to convert raw materials into parts, finished products, and assembly of parts. Instruments and control systems must also be designed, implemented, and maintained for peak performance.

- Designing processing equipment and procedures involve components for:

- Industrial compressor and turbine applications

- Processing operations

- Maintenance of equipment

- Troubleshooting processing

- Working with pumps that maintain the flow

Compressors and turbines must be designed for optimal power to operate systems. Time spent designing the right type of process control devices and equipment results in the peak performance of the processing system.

Process Design Is an Essential Function of Operations Management

Process design is creating or developing the essential parts of processing lines or systems. Each part must mesh well with all others to achieve optimal performance of the workflow. As a part of operations management, engineers and technicians lay out the completed design, test it, use it, and improve upon it.

Every company that produces goods does so with one or more processes. Processes transform resources or primary inputs into outputs for sale. Process design completes these activities:

- Create the number and sequence of processing steps

- Consider the variety of products – standardized or customized

- The volume of output and its quality

- The technology needed for the best results

- Training employees to the correct skill level

- The duration of the process runs

Next, we must examine the skills and knowledge needed for process design and technology.

| “Process design and process technology are parts of a specialized branch of process engineering where technicians work under the direction of engineers. They form a team to work with robotics, electrical systems, mechanical systems, and control systems.” |

Skills and Knowledge Needed for Process Design and Technology

The skills and knowledge needed for process design and technology are acquired by earning an associate degree. Students learn the essentials of basic and industrial electricity and math to configure electrical circuits. They also gain a working knowledge of these components:

- Programmable logic control basics

- Analytical devices and hydraulics

- Basic valves and final control elements

- The roles of temperature and flow

- Process control theory

- Design and optimization of control processes

Students are exposed to the essentials of personal computer applications, technical writing, industrial safety, and environmental practices. All these skills and knowledge prepare students for entry-level positions in numerous industries.

Industries Where Jobs Are Available for Associate Degree Holders

Graduates may find employment in several industries where they will operate processing equipment in their positions. The industries include, but are not limited to:

- Aeronautics and Automotive

- Ceramics and Chemical

- Foods and Metals

- Paper and Pulp

- Petroleum and Power

- Textiles and Water Treatment

These industries create products we use in everyday life that support our economy, and infrastructure, and meet personal demand. There is a consistent need for technicians in those industries that provide essential products. Prospective employees will find entry-level jobs in many states, especially those with growing populations and commercial enterprises. The best way to work in these fields is by earning an associate degree.

ITI Technical College: A Top Process Technology School

The best place to earn a degree is a school that is endorsed by the North American Process Technology Alliance (NAPTA). ITI Technical College has been a member of this organization since 2018 and continues to achieve its high level of standards. Why not request more information about our Associate of Occupation Studies (AOS) Degree and our Process Technology Program? It is the gateway to entering your career. Contact us today for more information.

For more information about graduation rates, the median debt of students who completed the program, and other important information, please visit our website at: https://iticollege.edu/disclosures/